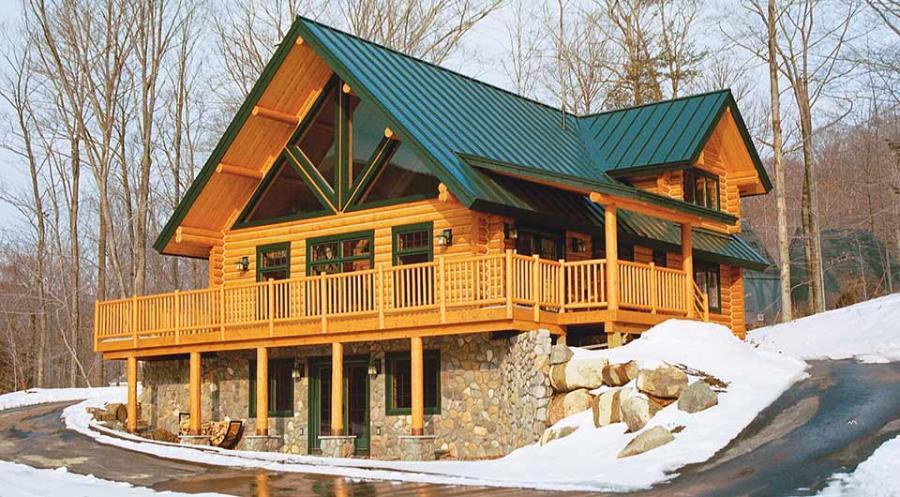

Steel and Aluminum, Two Great Metal Roofing Materials

Steel and Aluminum Strengths

If you are a designer or builder considering a standing seam metal roof system you may be asking the question what is the difference between aluminum and steel as a choice for the metal roof.

Commercial and residential metal roofing is primarily made of steel or aluminum. Both products are initially produced in giant rolls at a mill. All steel roofing has a protective barrier on both sides of the sheet called a metallic coating which protects against rusting. This is underneath and separate from any paint which imparts color to the product. There are two types of metallic coatings used: galvanized, which uses 100% Zinc in various thicknesses depending upon the product usage, and Galvalume, a mixture of aluminum and zinc. These metallic coatings “sacrifice” themselves to protect the iron in steel from oxidation when exposed to air and moisture. Zinc is a more “active” metal than iron so it oxidizes first and forms a protective barrier — zinc oxide, before the iron in the steel can become Ferric Oxide (rust). When zinc is combined with aluminum to form Galvalume there is even more protection in most circumstances.

Steel residential roofing is made in thicknesses designated by gauge and is generally 24 to 26 gauge, with the higher gauge being thinner than the lower. These gauges are appropriate since most residential metal roofing applications are over a solid substrate. Aluminum residential metal roofing is designated by decimal thickness and ranges from .023 to .040 thickness.

Steel and Aluminum Performance

Steel and aluminum both perform well as a metal roofing material. However, aluminum roofing, depending upon the exact product chosen, can run up to 20 percent higher in price compared to steel roofing.Aluminum is extremely resistant to corrosion caused by seawater, while steel is bit more susceptible to seawater damage over time. Consequently, the warrantees offered on the coil’s coating will be different as well. Both steel and aluminum perform pretty much the same, but the finish warranty for “coastal” areas is not provided for the steel panels. This is because of the potential for the coating to separate from the metal substrate at the edges, creating rust in environments that are near bodies of salt water. Exposure testing, however, has proven that Galvalume is up to three times more effective in preventing rust than galvanized steel material.

Aluminum is also lighter than steel if weight is a critical factor in determining the roofing material for your project. Both materials are very lightweight in comparison to other materials including asphalt shingles. Steel roofing is very lightweight with the heaviest product weighing about 1.5 pounds per square foot when installed. But aluminum is usually the lightest metal used for roofing. Its strength-to-weight ratio is among the highest of the “common” metals–that’s why airplane designers use aluminum for air frames. This lightness and thinness also means aluminum roofing material stores very little heat and also becomes cool quickly once it stops receiving direct sunlight.

Aluminum is more malleable than steel, allowing it to be configured into more complex profiles. However, especially in simpler profiles, you need fairly heavy gauge aluminum and that will boost its cost.

Steel inherently has more strength than aluminum, it’s usually less expensive and it’s more fire resistant without underlayment. Aluminum does not have a Class A fire-rating but the system can achieve a Class A rating with the proper underlayment and sheathing.

Both metal roof types will probably outlive all of us. Compared to traditional roofing materials, both offer a much longer lifespan, better environmental sustainability, better strength and a lower long-term cost. Steel can usually withstand winds of 110-150 mph and the material design of some steel roofs meet Miami-Dade and Florida Building Code requirements for hurricane wind uplift resistance.

Noise from rain, snow and small hail stones isn’t an issue for aluminum or steel roofing material–no more than it is for a shingle roof. That’s because it’s the sheathing and underlayment below the roofing material—on any roof—that blunts nature’s noises—not the roofing material itself.

Coatings for both aluminum and steel metal roofing coil come in a wide variety of standard colors and can be customized to meet the owner’s request. Custom colors generally cost more and certain coatings are more durable than others. For example, a Kynar PVDF coating offers additional protection against corrosion and oxidation.

Both aluminum and steel are two of the best energy efficient roofing materials. Both naturally reflect light and emit heat. Most aluminum and steel roofing material is available with cool roof coatings that meet LEED compliancy.

Ultimately, the needs of your project are going to dictate which you use. If the project is near the ocean and not in hurricane territory, the choice will probably be aluminum. If you’re out West building a wide-span storage building and brushfires are a concern, you’ll probably want to go with steel. If your concern is the added weight of a metal roof being retrofitted over an old shingle roof on an existing building, then you may want to think aluminum or a light gauge steel. Tap the metal that bests meets your needs.